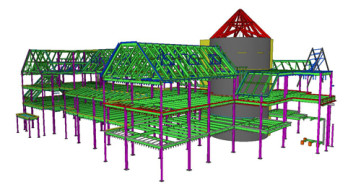

Liphart Steel prides itself in providing the highest quality of detailing to its customers by maintaining teams of experienced detailers and modelers, both in house and through our subcontractors. As a standard, all of Liphart’s projects are modeled using 3D software, regardless of the size or the complexity.

Liphart is able to provide compatible models for clash detection and coordination using a wide variety of software types (i.e., Revit, Navisworks, Tekla or SDS/2). Further, using this software, we are able to download information from the model to our fabrication equipment allowing us to productively provide a quality product to our customers. This technology also gives Liphart Steel the ability to track every piece of steel through the various fabrication stages.

Additionally, Liphart Steel routinely employees a quality firm of licensed professional engineers to complete connection design on its projects. This gives us the ability work closely with the Engineer of Record in developing a confidence in the quality of the delegated design.